“You’ve got to spend money to make money.”

We all know the saying but let’s be honest: Right now, spending can feel a little counter intuitive.

Designing, building and maintaining meat processing facilities has been part of Wiley’s core services for decades. Working extensively with our clients gives us a unique insight into the commercial reality of investing in upgrade works. And having delivered hundreds of millions of dollars’ worth of works, we believe that more often than not, the numbers stack up.

Wiley’s Design and Engineering Practice Manager Phil Hutchison suggests that investment can often be misunderstood when the full value of upgrade works is not articulated well.

“The reality is that a small investment now can transform into many millions over a decade, with some clients achieving return on investment in less than three years,” says Phil.

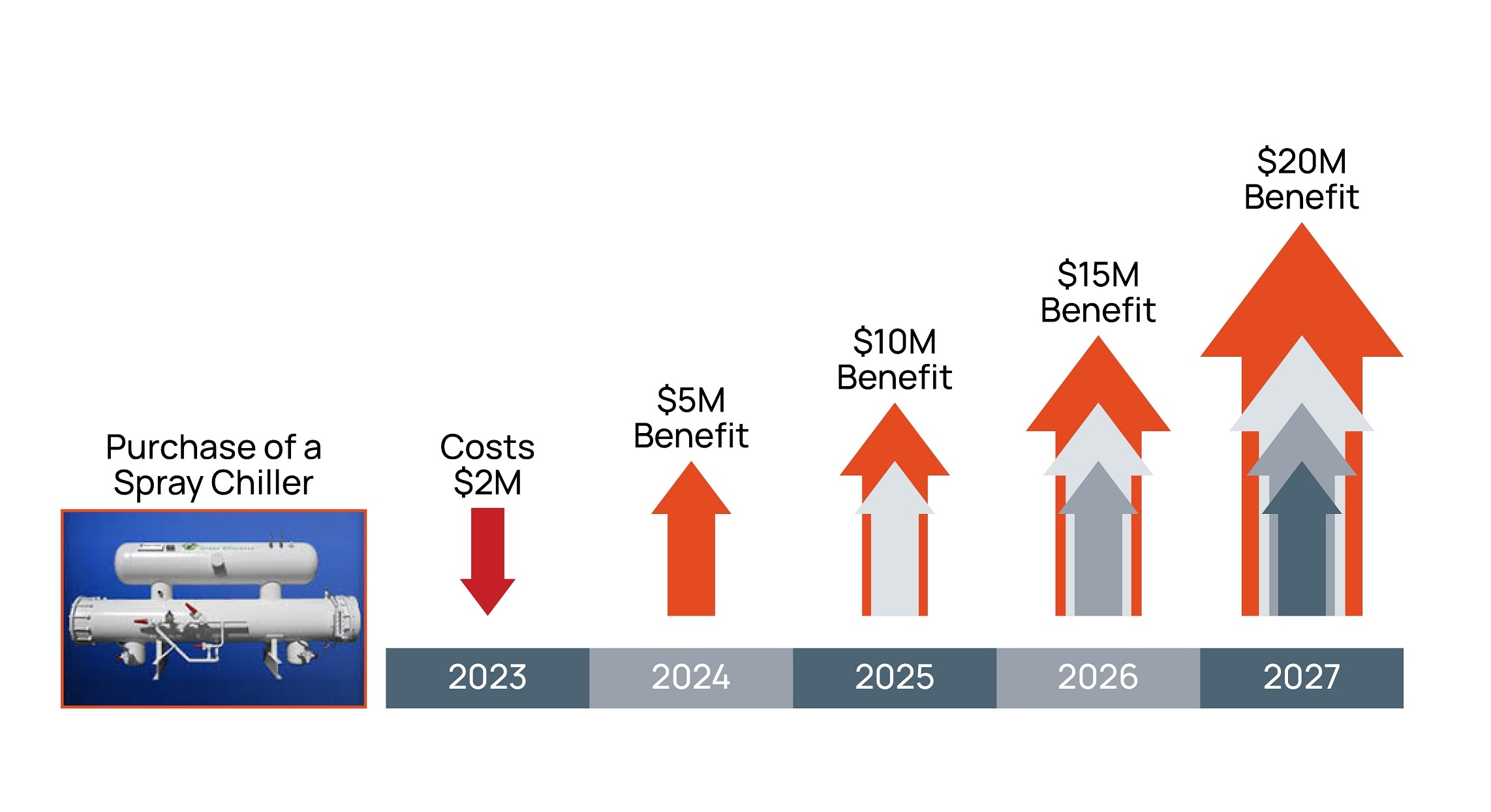

This article looks at three investments to illustrate our point. Let’s start by looking at the ROI of a carcase spray chilling installation in the graph below.

Processors have long accepted that water evaporation in the carcase chiller can cause product weight loss of as much as 3%. But it doesn’t have to be that way. It usually costs around $2 million to equip a facility with spray chillers, and long-term results are impressive.

Processors have long accepted that water evaporation in the carcase chiller can cause product weight loss of as much as 3%. But it doesn’t have to be that way. It usually costs around $2 million to equip a facility with spray chillers, and long-term results are impressive.

In 2011, Meat & Livestock Australia published some compelling numbers on spray chiller trials at a facility in Dinmore in Queensland. They found the spray chiller reduced carcase weight loss to a low of 0.47%, which produced an average saleable meat increase of 0.53% per carcass.

“Now, let’s say your facility has a daily throughput number of around 900 head at 300kg each,” explains Phil. “That means you can expect to see an average increase of around 1400kg of saleable meat, daily.”

On average, a meat processor can likely expect to make an additional $5 million each year from that extra meat. That’s $50 million after 10 years, on a one-off $2 million investment. Pretty convincing stuff.

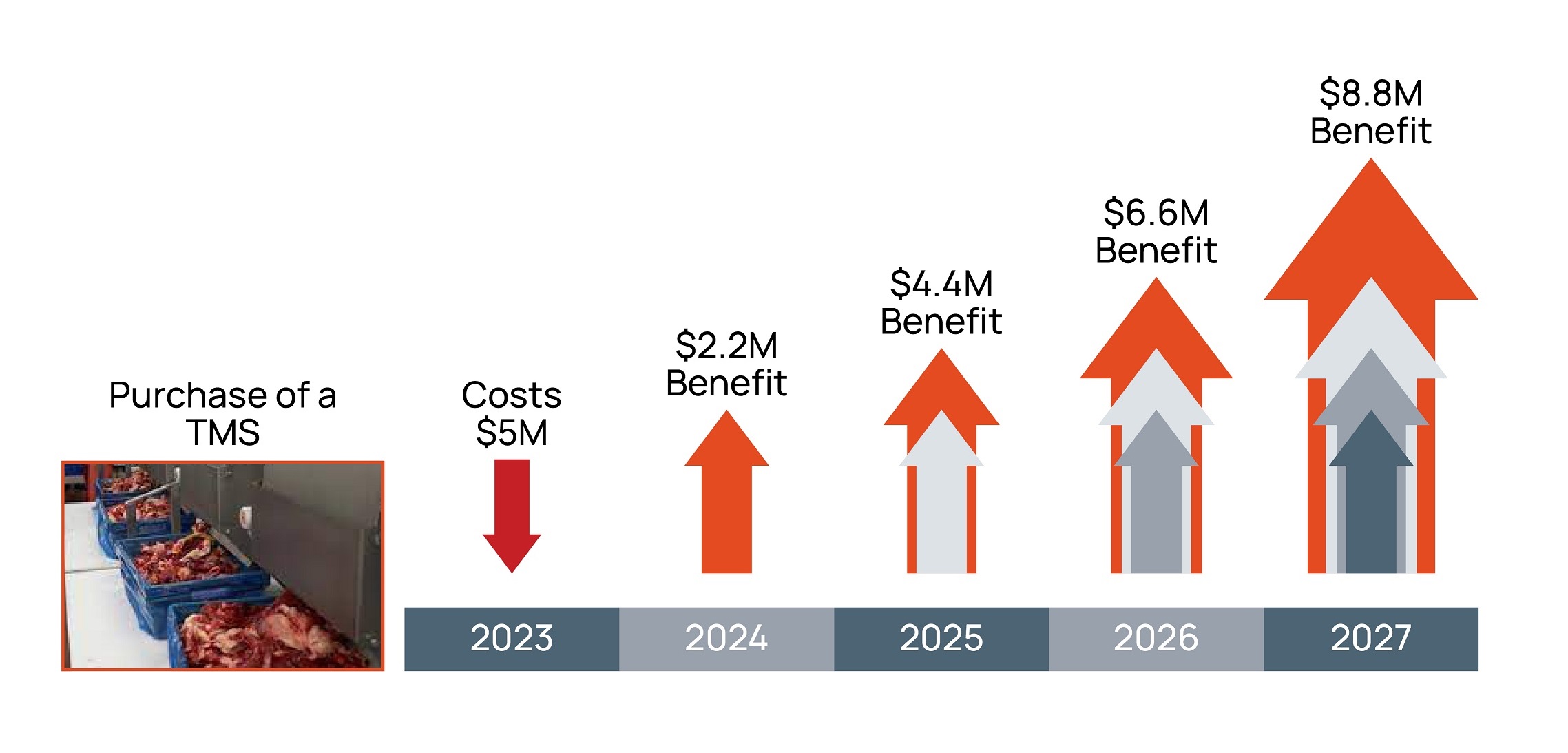

Lean meat giveaway was also an accepted part of packing meat, but not anymore. A trim management system (TMS) will allow you to fill your cartons more accurately according to the chemical lean printed on the label.

Lean meat giveaway was also an accepted part of packing meat, but not anymore. A trim management system (TMS) will allow you to fill your cartons more accurately according to the chemical lean printed on the label.

A TMS line can cost $5 million, but will return on average about $2.2 million annually in savings. Minus your original investment, that’s $17 million extra in the bank after ten years.

It’s worth pointing out that all figures here are estimates. With meat continuing to increase in value as developing nations eat more meat products, actual ROI could be much higher.

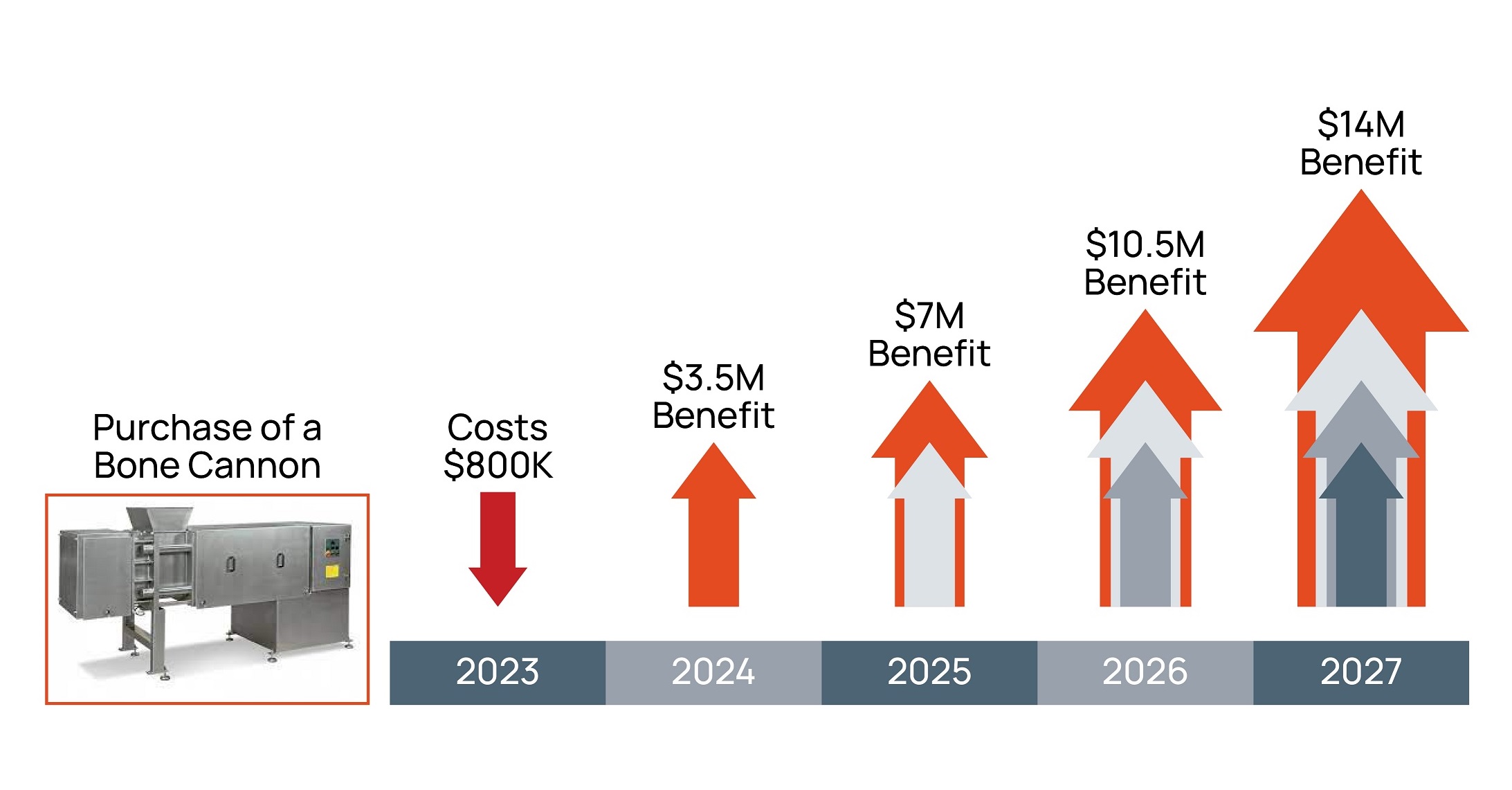

Here we’re looking at the cost and benefits of investing in a bone cannon. Say there’s a small amount of meat left on the bones you send to rendering. You may not currently have the tools to collect that meat, nor the capacity to freeze it. But investing in a bone cannon has a clear cumulative economic effect.

Here we’re looking at the cost and benefits of investing in a bone cannon. Say there’s a small amount of meat left on the bones you send to rendering. You may not currently have the tools to collect that meat, nor the capacity to freeze it. But investing in a bone cannon has a clear cumulative economic effect.

A bone cannon can cost around $800K but delivers an average return of $3.5 million in saleable meat each year. If you’ve got refrigeration capacity, this is a great investment on its own. But what if you don’t?

“A new freezer can cost $10 million, which is a significant investment – but in conjunction with a bone cannon, it will pay itself off in about three years,” says Phil.

“And then it’s potentially an extra $3.5 million in saleable meat every year after that.”

It’s worth noting the above numbers are estimates only, but our team are more than happy to have a chat about your specific needs and help develop an estimate of the investment for your specific facility. And keep in mind that we can also help our clients secure grant money, and especially for sustainability upgrades, so you don’t necessarily have to find the full cost of investment yourself.

Want to learn more? Call us today or send us an email.