Product traceability is a major focus for manufacturers today. Wiley’s Glenn Jacobsen describes how the latest processing technology contributes to product integrity.

TRACEABILITY relates to the ability to ability to track and identify product throughout the production operation, out across supply and retail chains and into the homes of consumers.

Thanks to recent spate of high profile product recalls, it’s never been more important to have advanced track and trace systems in place that can quickly identify, find and detain all ‘at risk’ products at any point of the process and supply chain.

Labelling practices are key to achieving absolute traceability. Twenty years ago, I worked in a meat processing and exporting operation that had such a labelling system, which was all the more impressive for being manual. Hand applied labels with coding captured batch, weight, date and other information vital to maintaining a complete and accurate record of everything that passed through their processing operation and out to customers.

In the last five years, food manufacturing companies have been increasingly taken to task over their ability to clearly communicate the make-up and origin of their product, down to its ingredients and raw materials. This demand for transparency is driven even higher by consumers with specific dietary needs and/or allergies to consider.

Retail chains and the big supermarkets are, more than ever, dictating the properties of the end-product they are prepared to stock and sell. Their standards have strict clauses specifically aimed at the label integrity and traceability of all the products they will carry. The top two standards manufacturers have to comply with if they want their product on Woolworth’s shelfs, for example, are Product Identification and Traceability.1

With the advancements in technology and systems over the last two decades the industry is now at a point where all food manufacturers, especially those looking to export their goods, need to plan their operations with traceability at the foundation of their work and material flows.

With that in mind, here are some of the emerging technologies that can help keep traceability at the core of your manufacturing operation.

Warehouse Control and Warehouse Execution Systems (WCS/WES)

Line control software systems that integrate and manage the entire manufacturing process. From raw material coming in to completed product going out technology at every stage identifies, records and communicates with the core system. This allows for immediate location, and if need be, extraction and isolation of specific items or ranges of items.

Automation

Automation is not new, being commercially available and utilised for years in the automotive industries. It is however only recently begun to become an integral part of many modern food manufacturing lines as it becomes cheaper and more specifically designed for food production tasks and environments.

A popular new development sees smaller, more collaborative robots being designed for use in the areas of picking, sorting, packing and palletising to work seamlessly alongside human operators to maximise the enforcement of quality assurance measures.

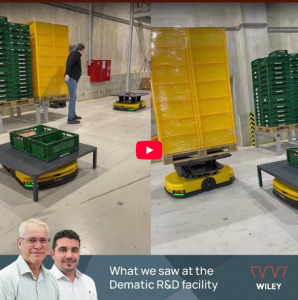

Comprehensive Automated Storage and Retrieval Systems (AS/RS) and Automated Guided Vehicles (AGV) provide complete stock control solutions for cold storage and warehousing and give another level of traceability with real time storage and production data feed directly into the WCS.

High speed in-line scanning

Issues arise as each product line becomes more automated and less people are actively viewing the product. To answer this, a sub-set of robotic technology has emerged with traceability at its heart. High speed vision scanners read every label on every item on the line as it passes to verify its quality and identification information prior to packing.

Functional packaging and process

For the first time in retail history the packaging of a product no longer serves solely as a marketing tool. We are seeing the product design process flipped on its head with packaging designed to more clearly display the ingredients and origin of its contents and production and incorporate the all-important coding that will be its unique DNA and traceable fingerprint throughout its journey from process to plate.

The rising trend in ready-to-eat and prepared meals is driving processing techniques like High Pressure Pasteurisation into the spotlight also sees packaging is being re-designed to make the most of these new processes. Europe is leading the way, developing new films (e.g. microwavable, ovenable, freezable, breathable) that are recyclable and also work with the process to extend the shelf life of the food. Tweaks in the shape of food and beverage containers allow for more units to fit in the pressurisation chamber significantly improving production rates and optimising energy usage per unit.

1 Section 5 of the Control of Product section in the Woolworths Quality Assurance Standard for Manufactured Food.

Article origianally published in Food & Drink Business magazine