The annual Supply Chain & Logistics Awards took place in November in Sydney, Australia. These historic and prestigious national awards, presented by the Supply Chain & Logistics Association of Australia (SCLAA), are in their 57th year, making them well sought after, recognised and influential awards across the supply chain, logistics and transport industries.

With a record number of entries received in 2017 of an exceptionally high calibre, all award winners were amongst good company.

We are proud to share that Northern Cooperative Meat Company (NCMC) were the winners of the 2017 Information Technology and Management Award.

Information remains the most important requirement of any supply chain. Information technology is where the majority of supply chain improvements have been made. Nominees for this award demonstrated where their use of existing or new technology provided significant improvements to their management of information and/or their supply chain processes.

NCMC implemented a world-first meat processing, buffering, sortation and sequencing solution, developed in response to the increased demand from Asia for Australian red meat.

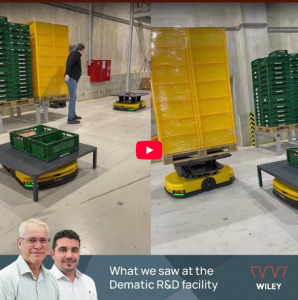

In NCMC’s materials handling system, from the time the cartons leave the boning room until they are inducted to the Dematic Multishuttle automated storage and retrieval system (ASRS), they are never touched by hand.

Integrated conveyors transport cartons through various production processes. When frozen, the finished goods are conveyed and inducted to the ASRS, which can accommodate 4,300 cartons for automated buffering, order building and sortation. This multifaceted project was designed and delivered by Wiley and supplied and integrated by Dematic.

All materials handling is fully automated and driven by smart location control and route software. The system directs cartons to be sorted in locations which minimises carton processing and retrieval time. When the system is not required to fulfill orders, it undertakes housekeeping, rearranging the location of stock within the ASRS to minimise order retrieval times.

NCMC’s ground-breaking system resulted in the elimination of manual handling of frozen cases, the new lidding system improves presentations and stacking, there is full track and trace capability increasing product selectivity, significantly reduced labour and time required to sort orders, a smaller system footprint and reduced product damage.

All these benefits have made NCMC more competitive and responsive to its customer, and improved the working conditions for its team members.

Wiley collaborated with NCMC to design and deliver their recent cold chain upgrade, new knocking box and tannery upgrade. These projects have futureproofed the Casino community.

Wiley Project Manager, Barry Murphy said “I would like to congratulate NCMC on their fantastic win. I really enjoyed my time collaborating with NCMC on this project and we are exceptionally proud they won this well-deserved award from the SCLAA. We are proud to work with proactive and future focused companies like NCMC, who have a team approach to finding better ways and solutions that mirrors our values. I would also like to thank all the members of the Wiley team, past and present, who contributed to the success of the project.”

“Thanks especially to Barry Murphy and all involved from Wiley to enable this win” said Greg Williams, Group Engineering Manager at NCMC.

The NCMC, Dematic & Wiley Team at the awards

We look forward to a continued partnership with NCMC as they lead their community and industry into the future.